Project 7

Closed-loop digital pipeline for a flexible and modular manufacturing of large components

The project

Manufacturing and repairing of large-scale parts, usually one-of-a-kind components, is a complex and challenging process that requires the implementation of holistic data management and integrated methodology capable of ensuring the manufacturability, quality and high-precision of the large-parts from the engineering stages (i.e. design, simulation/modelling and production planning). Large-part manufacturing is characterized by the high customization required (built-customer specific) and this high degree of personalization implies a great effort in the design and the posterior verification after manufacturing, to achieve high precision.

On the other hand, this customized product-centric design requires an optimization of the resources of the workshop –i.e. workers, machines, devices— for a responsive, reconfigurable and modular production, targeting the execution of key labor-intensive tasks by preserving industry-specific workers’ knowledge and skills (worker-centric approach). With this in mind, the EU-funded PeneloPe project will develop a methodology linking product-centric data management and production planning and scheduling in a closed-loop digital pipeline.

Objectives

The PeneloPe project aims to develop a novel closed-loop digital pipeline, an end-to-end Digital Manufacturing solution, enabling a bidirectional dataflow for seamless integration across the entire manufacturing value chain. The PeneloPe solutions will be implemented and demonstrated in four industrial-driven pilot lines in strategic manufacturing sectors (Oil&Gas, Shipbuilding, Aeronautics and Bus&Coach) and with potential replicability to other sectors. The PeneloPe project envisions to highly-increase EU manufacturing sector competitiveness by increasing production performance, quality and accuracy while ensuring workers’ safety and resource efficiency.

The result is the PeneloPe vision for an end-to-end modular, scalable and networked manufacturing architecture:

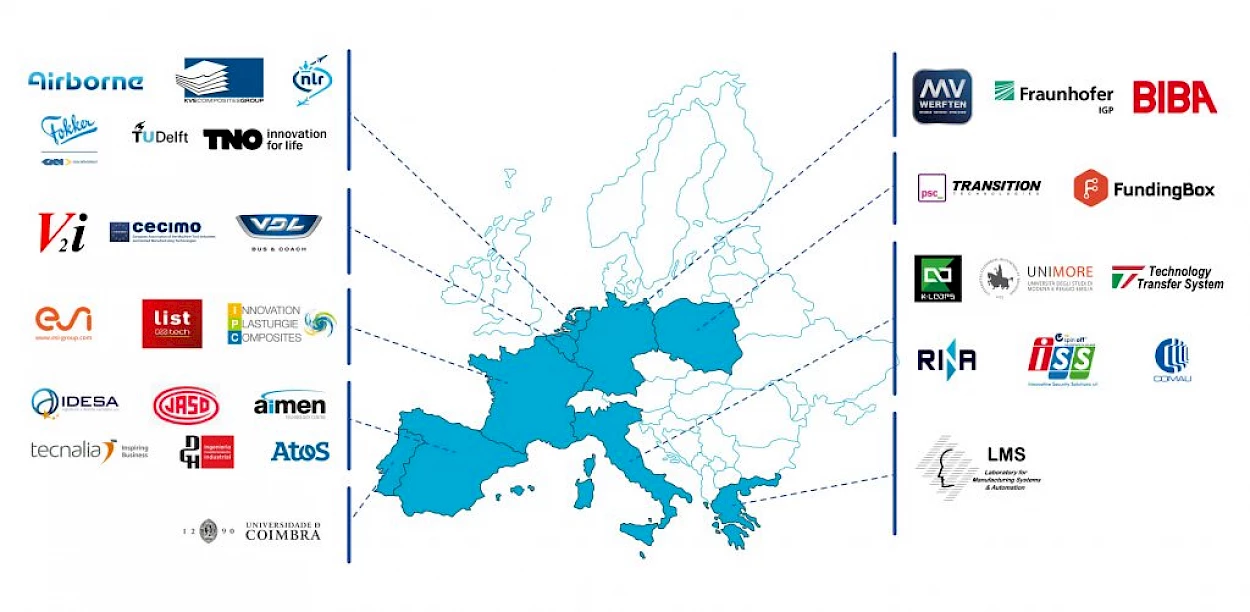

Consortium

The PeneloPe project involves the collaboration of 31 partners across the European Union that work together to develop a novel closed-loop digital pipeline based on the development of modular and reconfigurable production approach for the manufacturing of high-precision large-scale parts. PeneloPe partners are already a well-integrated pan-European network of RTOs, industrial integrators, high-tech companies and end-users, encompassing a great number of previous R&D initiatives, DIH’s and manufacturing pilot lines. The consortium will use the PeneloPe project to further extend their capabilities, services, products and network, impacting, in the process, thousands of EU manufacturing companies and their sectors.

See below the partners that make PeneloPe possible.

PeneloPe @UC

At University of Coimbra,