INTEGRADDE

Intelligent data-driven pipeline for the manufacturing of certified metal parts through Direct Energy Deposition processes

The project

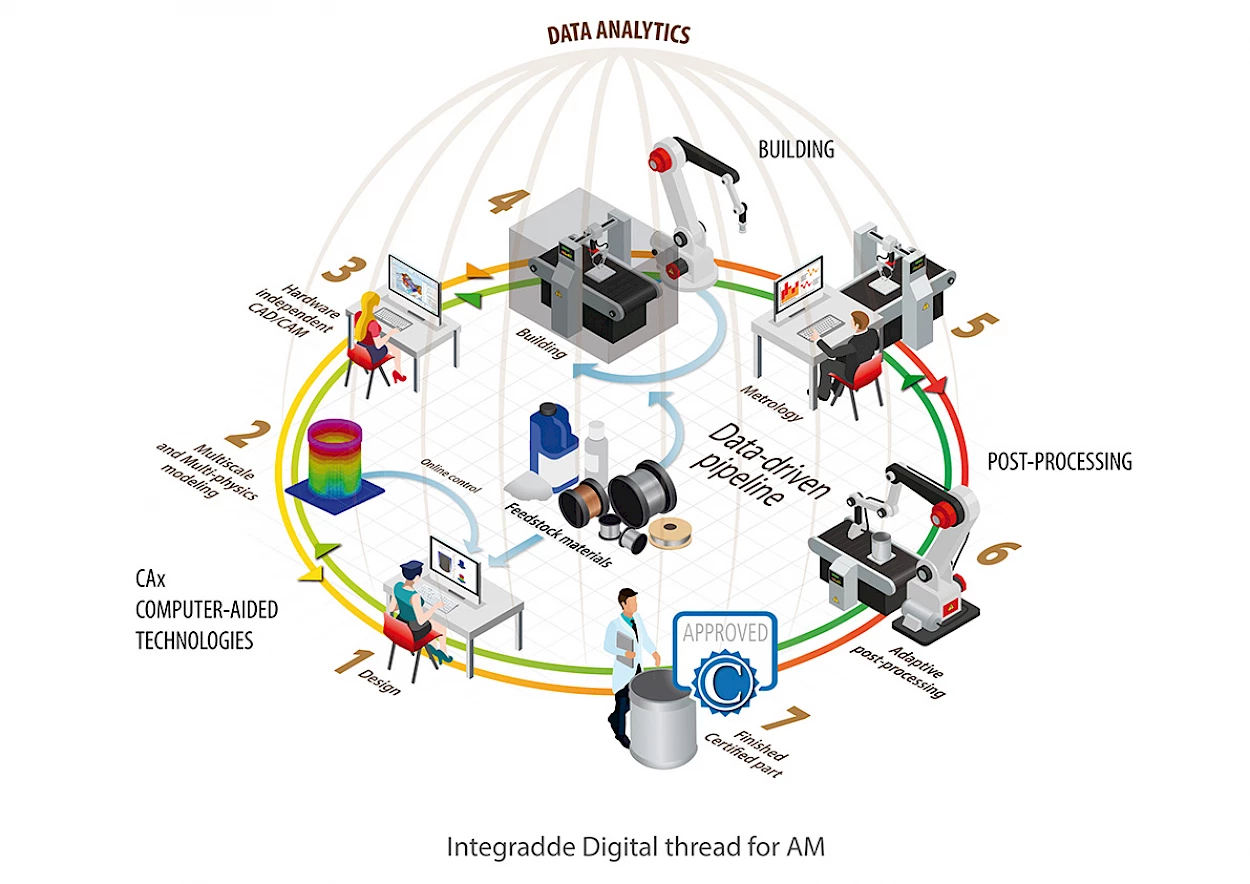

Breakthroughs in additive manufacturing and metal part construction have led to high demand for optimisation solutions that would increase efficiency throughout the production process. The EU-funded INTEGRADDE project will meet this need by introducing a digital manufacturing solution that would allow the efficient implementation of automation and holistic data management throughout the additive manufacturing chain. This methodology would guarantee high levels of quality, durability and efficiency for metal parts by using direct energy deposition across the chain, optimising processes and making predictions using AI-simulated models, reducing defects and allowing for integrity throughout the workflow.

The industrialisation of Additive Manufacturing (AM) requires a holistic data management and integrated automation. INTEGRADDE aims to develop an end-to-end Digital Additive Manufacturing solution, based on DED technologies [i.e. Laser Metal Deposition (LMD) for manufacturing of complex geometries in medium-sized components with higher accuracy, and Wire-Arc Additive Manufacturing (WAAM) for simpler geometries with higher deposition rates], enabling a cybersecured bidirectional dataflow for a seamless integration across the entire AM chain.

Objectives

The goal is to develop a new manufacturing methodology capable of ensuring the manufacturability, reliability and quality of a target metal component from initial product design via Direct Energy Deposition (DED) technologies, implementing a zero-defect manufacturing approach ensuring robustness, stability and repeatibility of the process. To achieve this aim, INTEGRADDE addresses the following key innovations:

- Development of an intelligent data-driven AM pipeline.

- Combination of automatic topology optimisation algorithms for design, multi-scale process modelling, automated hardware-independent process planning, online control and distributed NDT for the manufacturing of certified metal parts.

- A self-adaptive control is adopted focused on the implementation of non-propagation of defects strategy. Moreover, Data Analytics will provide a continuous refinement by acquiring process knowledge to assist in the manufacturing of new metal components, improving right-first-time production by adopting a mass customization approach

- Cybersecurity ensures data integrity along the AM workflow, providing a novel manufacturing methodology for the certification of metal AM parts.

INTEGRADDE implements a twofold deployment approach for the pilot lines: both in application-driven at five industrial end-users (steel, tooling, aeronautics, and construction) and open-pilot networks at RTOs already owning AM infrastructure (AIMEN, IREPA, CEA, WEST). This will allow a continuous validation and deployment of specific developments towards industrialization, boosting definitive uptake of AM in EU metalworking sector.

Consortium

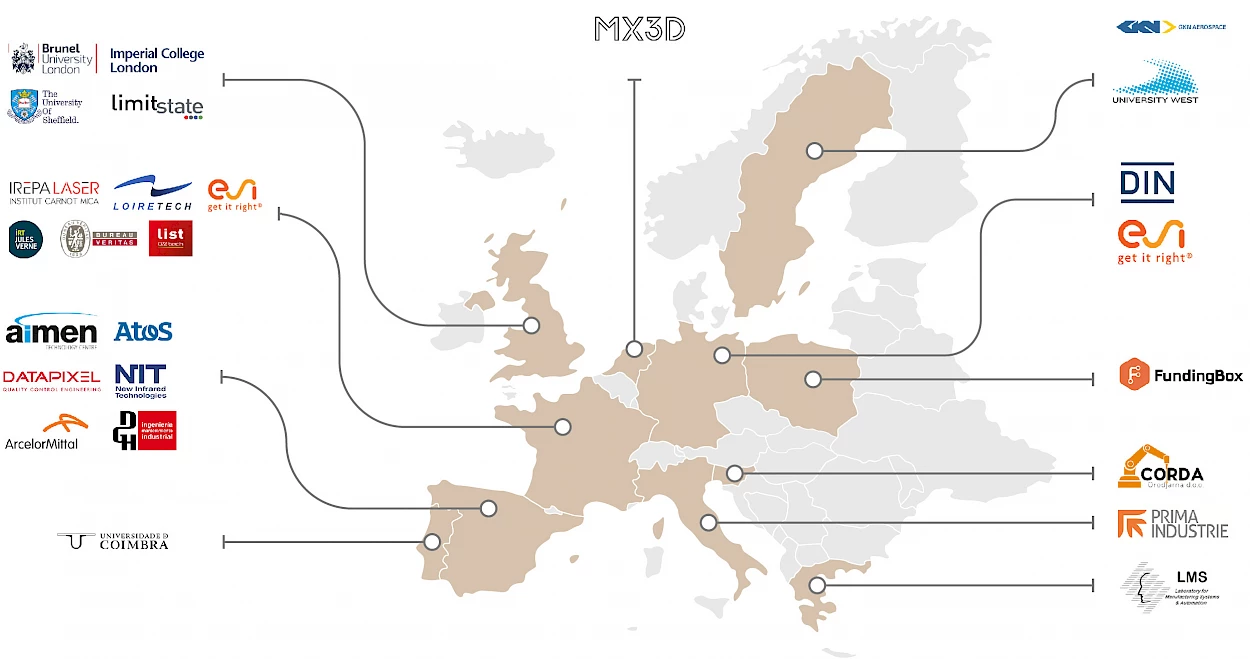

The INTEGRADDE project involves the collaboration of 26 partners distributed across Europe and is led by AIMEN (Asociación De Investigación Metalúrgica Del Noroeste and Technaid SL).

See below the partners that make INTEGRADDE possible.

INTEGRADDE @UC

At University of Coimbra,

Related Publications

Nome do artigo [www] [pdf]