ComMUnion

Net-shape joining technology to manufacture 3D multi-materials components based on metal alloys and thermoplastic composites

The project

Carbon Fibre Reinforced Thermoplastic (CFRT) materials are at the cutting edge of technologies for the automotive and aerospace industries. Yet the way they are manufactured and assembled can compromise the full potential of their performance. With new joint manufacturing technology, cutting-edge materials can achieve greater performance at a fraction of the cost. The ComMUnion project combined several innovative technologies into a robot-led assembly process which will enable the productive and cost-effective manufacturing of high-performance 3D metal and CFRT materials. Automatic tape placement of CFRTs with controlled laser-assisted heating, high-speed laser texturing and cleaning, online monitoring and inspection, and computational multi-scale modeling will be combined in a multi-stage robot solution for joining to provide the greatest performance joints. Tools for quality diagnosis and decision support will be also implemented under a cognitive approach.

Through the ComMUnion system, mechanical performance in the automotive sector can be increased by up to 30%, or the same performance level can be maintained while reducing vehicle weight. This brings environmental benefits as well as functional ones. Using less metal during manufacturing decreases the environmental impact, while weight reduction leads to lower fuel consumption and GHG emissions. This translates to a 10-15% reduction in the carbon footprint and a 10% reduction in the overall environmental impact.

Objectives

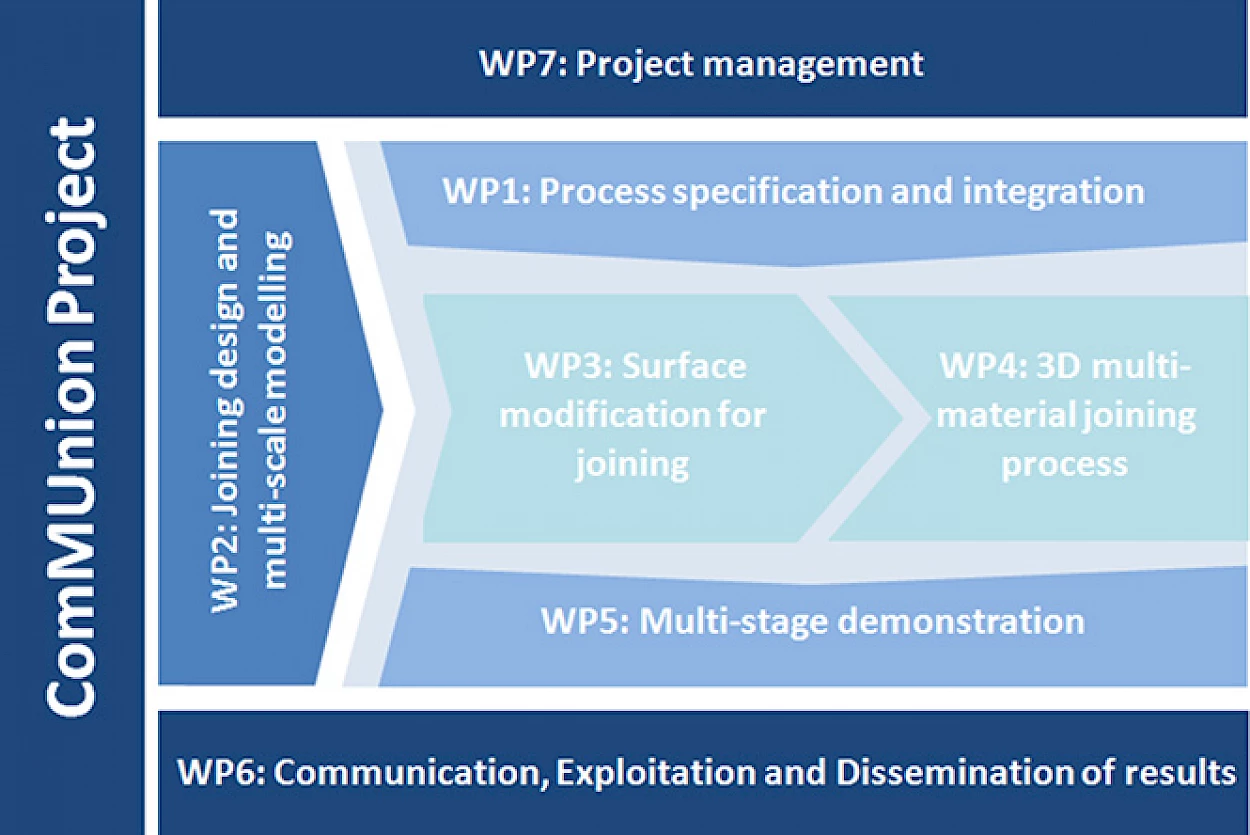

The major goal of ComMUnion was to develop a novel solution for manufacturing metal reinforced-CFRT multi-material components by addressing all the relevant value chain. A multi-stage advanced joining process was developed. This joining process combines state-of the art automatic placement of CFRT tapes with controlled laser-assisted heating, high-speed laser texturing and cleaning of metallic surface, and on-line monitoring and inspection for the manufacturing of new complex 3D components with enhanced properties. ComMUnion relies on a robot-based approach that also enables on-line inspection for layer-to-layer self-adjustment of the process. Moreover, tools for multi-scale modelling, parametric offline programming, quality diagnosis and decision support were developed under a cognitive approach to ensure interoperability and usability. The strategy proposed to achieve the main goals of the project is based on the completion of 7 Work Packages.

The figure below shows the interdependences of the Work Packages.

Consortium

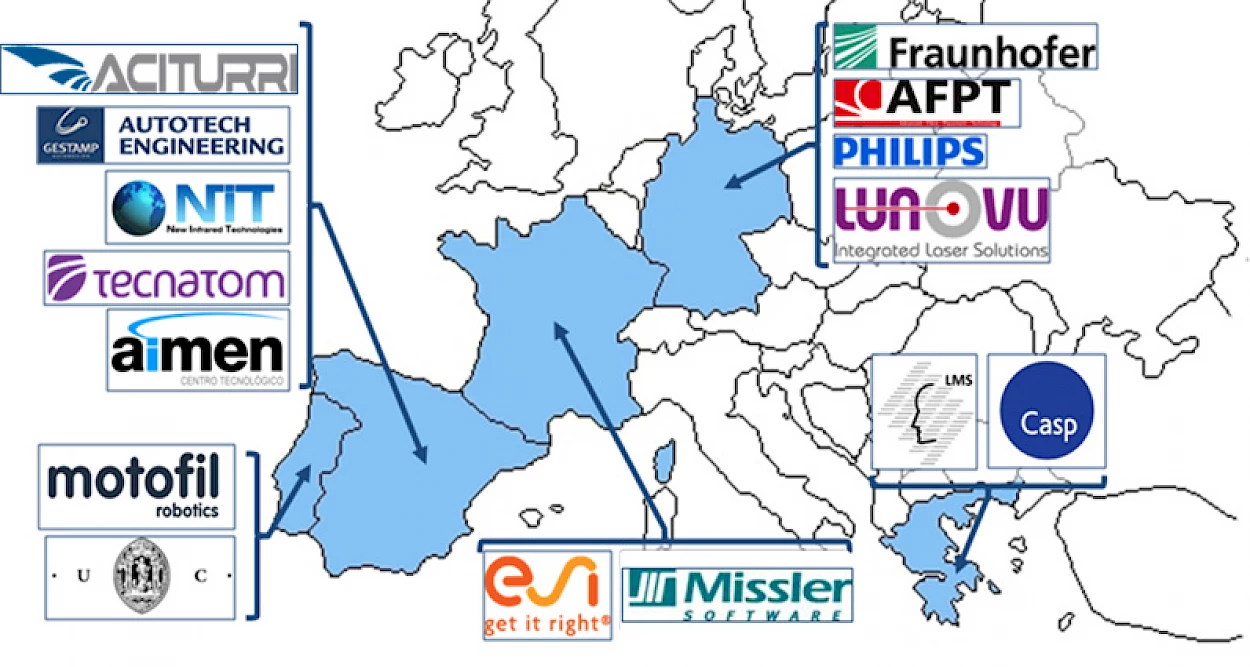

ComMUnion, coordinated by AIMEN (Asociación De Investigación Metalúrgica Del Noroeste and Technaid SL), brings an opportunity to put together all the expertise of 15 partners to develop a breakthrough concept applied to 3D metal/thermoplastic joining.

The figure below shows the European map distribution of the ComMUnion consortium.

ComMUnion @UC

At University of Coimbra,

Related Publications

Nome do artigo [www] [pdf]